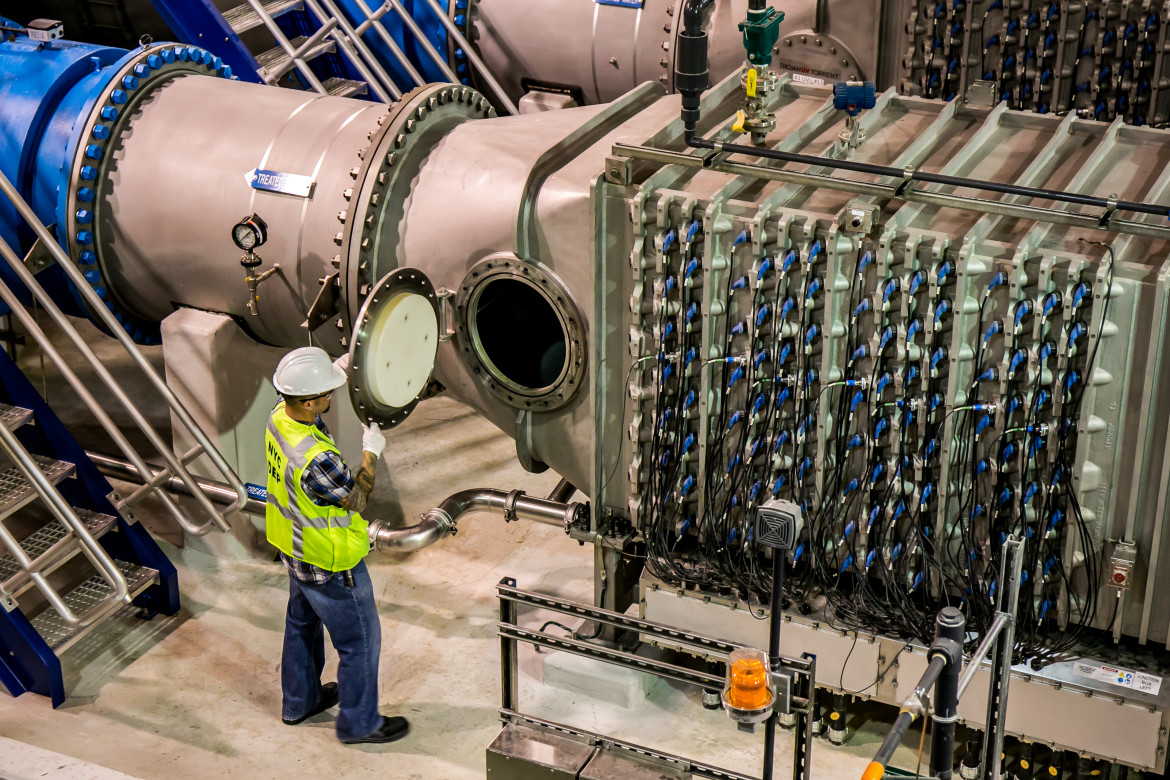

To ensure that water is safe for human consumption and suitable for various industrial processes, reverse osmosis technology is commonly used to treat water. However, one of the biggest problems is the accumulation of contaminants and sediments that cause wear on the membranes. But a new self-cleaning hybrid membrane technology can help the process.

Currently, the most energy-efficient technologies for desalination are based on membrane desalination and reverse osmosis (RO), which represents more than 60% of global desalination capacity.

The effectiveness and performance of membranes used in the desalination process are highly influenced by their structure, topology and surface chemical composition.

These attributes are determined during the manufacturing process and cannot be modified at will throughout the useful life of the membranes.

Challenges in Reverse Osmosis

For the reverse osmosis process, a semi-permeable membrane is used that acts as selective barriers, allowing water molecules to pass through while blocking larger impurities and contaminants.

One of the common challenges is the buildup of dirt and contaminants on the surface of these membranes, which reduces their efficiency over time leading to costly cleaning and replacement procedures.

Research between the New York University of Abu Dhabi and the CNR (Istituto per la Tecnologia delle Membrane) of Rende, Italy published in the journal Nature, has developed a self-cleaning hybrid membrane, which differs from semi-permeable ones thanks to the incorporation of crystals. organics sensitive to stimuli.

When these membranes are heated slightly above room temperature, the crystals react quickly and mechanically, activating the membrane.

This has a surprising effect: scale and contaminants that would normally clog the membranes are effectively removed.

Self-cleaning hybrid membranes offer a number of key benefits:

a) Increased Efficiency: By eliminating scale, smart membranes maintain a constant flow of water through the desalination process, improving efficiency and reducing the need for periodic cleaning.

b) Extended Useful Life: Self-cleaning allows the membranes to have a longer operational life, reducing maintenance and replacement costs.

c) Lower Environmental Impact: By avoiding the need for chemical cleaning and reducing the energy required, these smart membranes can have a lower long-term environmental impact.

d) Innovation in Desalination: This approach lays the foundation for the development of energy-efficient hybrid membranes, not only for desalination but also for other separation processes.

The need for fresh water is undeniable and urgent, and desalination is presented as a viable response to this growing demand. However, the sustainability of industrial desalination is a challenge that cannot be ignored.

Smart membranes with self-cleaning capabilities open a new door to a more sustainable future by addressing some of the most common problems of industrial-scale desalination.

Another solution to prevent the accumulation of dirt and reduce the wear of reverse osmosis membranes is with the help of a goodpretreatment system.

Zeolite as a filter medium to improve the performance of reverse osmosis membranes

Zeolite is a porous mineral that improves water quality in desalination plants by acting as a highly effective filter.

These features and strategies combine to extend the life of the membranes andreduce the need for frequent cleaning and maintenance.

This is especially important in reverse osmosis systems used in industrial and commercial applications, where efficiency and reduced operating costs are critical.

References:

(2023, september 16). Smart dynamic hybrid membranes with self-cleaning capability. Nature Communications. https://www.nature.com/articles/s41467-023-41446-9